To reliably connect two aluminum parts to each other without using fasteners, argon welding is best. But this pleasure is not cheap, so at home you can use the "artisanal" method.

For example, in a garage or workshop, you can weld aluminum using an ordinary grinder, using a nozzle made of an elongated nut and bolt. This method of welding aluminum billets is quite fast and quite reliable.

Preparatory work

We wind an extended nut with an M14 bolt onto the shaft of the Bulgarian engine. In order to reliably fix the bolt in the body of the nut, it is necessary to drill a through hole in it, in which we cut the thread and screw the two fixing bolts towards each other.

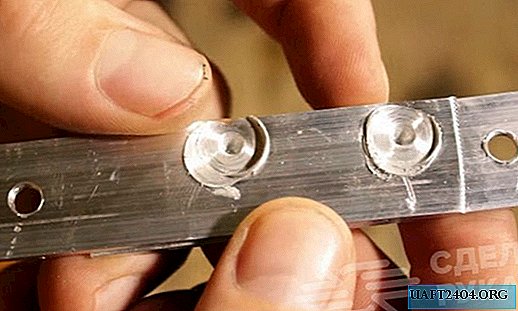

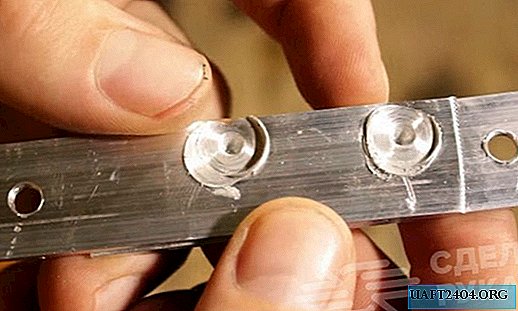

After that, we process the protruding part of the M14 bolt on a lathe or grind off everything superfluous using a conventional file. As a result, a part with a length of 3.5 mm should be obtained (the widest part of the nozzle is about 10-11 mm, and the thickness of the cone at the base is 3.5 mm).

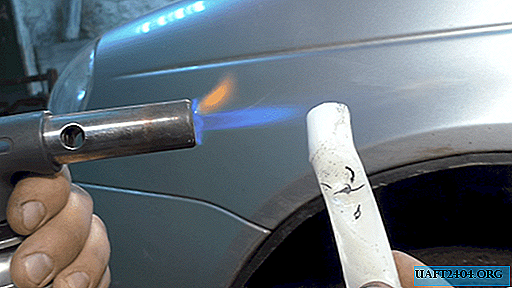

Welding aluminum using angle grinders

Using this method, it is good to weld aluminum plates. We lay the two blanks on top of each other, fix in the right position with the help of self-tapping screws, turn on the grinder with the installed homemade nozzle and you can start welding.

Bonding of aluminum parts occurs due to friction. In this case, the resulting welded joint can withstand a fairly large shear and tensile load. For more information about welding aluminum using angle grinders and testing welded parts for strength, see the video on our website.