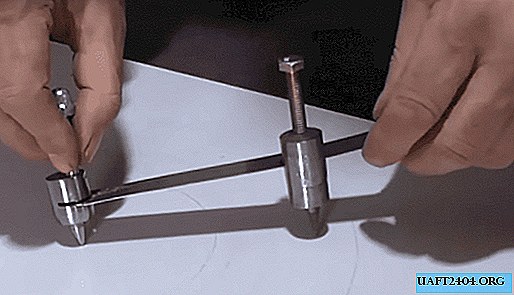

We managed to find an old vertical stand with a rectangular base of cast iron on the metal reception. Working stroke - from 0 to 100 mm. There is a transverse groove at the base, so you can fix the vice there to fix the workpieces.

It remains only to attach a powerful network electric drill to the rack, and as a result we get a mini drilling machine for the home workshop, with which it will be possible to drill even holes at right angles in steel and wooden workpieces.

The main stages of work

We will use the electric drill of the Soviet model (in addition to the cam chuck, cone drills can still be inserted into it), which is still working and has very good torque. Ideal for making a drilling machine.

However, to fix it on a stand, it will be necessary to carve a adapter sleeve (transition from a diameter of 54 mm to a diameter of 38 mm) with a length of 65 mm on a lathe. To do this, take a suitable steel disc in diameter and grind the desired part.

Then we clean the surface of the rack from rust and dirt, cover it with a layer of soil and spray paint (or auto enamel). We connect the electric drill through the adapter sleeve with the stand, and the compact drilling machine is completely ready for work.

To summarize

It turned out very cheap and cheerful. Therefore, if you see such an old stand, do not pass by - make yourself a useful tool. All stages of work on the "reconstruction" of rubbish from metal reception, see the video on the site.