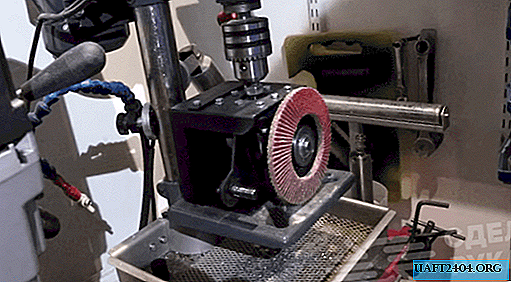

A working gear from an old grinder can serve as a good basis for the manufacture of a home-made grinding machine for a home workshop. Only in this case will an additional electric motor be required. However, as an option, a drilling machine can also be used as a drive.

First of all, it is necessary to disassemble the old non-working grinder into components, and then remove the gear mechanism from the housing. Bearings can be used with a native engine. Next, we proceed to the next stage of work on the manufacture of a grinding machine.

Grinding machine assembly process

First, based on the body of the angle grinder, it is necessary to make markings on a steel sheet 2 mm thick in order to assemble the box of a homemade grinding machine. Next, with the help of a grinder, according to the intended marking, we cut out blanks from the sheet of metal for assembly of the box.

After we cut out two rectangular plates, we bend them at an angle of 90 degrees on a mechanical bending machine. Then we fasten the reducer of the grinder, fasten the plates with clamps and weld them together.

At the next stage, we weld auxiliary elements from pieces of sheet metal to the main box. We fasten the lower part of the grinding machine body to the bed of the drilling machine, and fix the gear shaft in the chuck.

The result is a compact universal grinding machine, which can be used not only for grinding metal - any nozzles for grinders are suitable. The detailed process of making a homemade device, see the video on the site.