Conventional F-shaped clamps are not always suitable for gluing wide wooden panels - for the reason that they do not have enough length. Usually they use special clamps - wymes. If at hand there is nothing like wyme, you can make a long carpentry clamp with your own hands.

To make this home-made device you will need a profile pipe, trimming thick plates for clamping jaws, a metal strip, a stud (screw), a wing bolt with a spring and two nuts. All these materials can be cheaply bought at scrap metal collection points.

The main stages of work

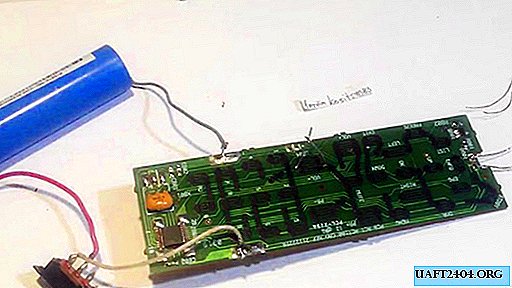

As a frame of a long clamp, a profile pipe 35x35 mm is used (a profile of other sizes can be used). It will also require two small pieces of pipe with side dimensions 40x40 mm, which will move around the frame.

Clamping jaws made of a steel plate 1.5-2 cm thick are welded to short sections of the profile. First you need to make diagonal notches (crosswise) on the clamping surface, and then the jaws are welded to the sections of the profile pipe.

An emphasis made of a piece of steel strip, as well as a round nut, into which a special wing bolt with a spring mechanism is screwed, is additionally welded on the main carriage with a clamping sponge.

In a long profile pipe (joinery clamp frame), holes are drilled in increments of 5-10 cm, and a piece of plate is welded to the edge to which two guide nuts for the studs are attached. The edge of the screw is sharpened under the cone, and a hole is drilled in the end. The screw itself abuts against the clamping sponge.

For a detailed process of manufacturing and assembling a long joiner's clamp from a professional pipe and metal scraps, see the video on the website.