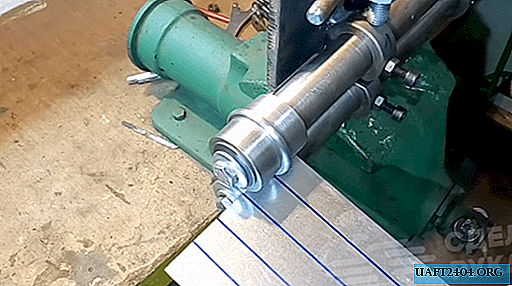

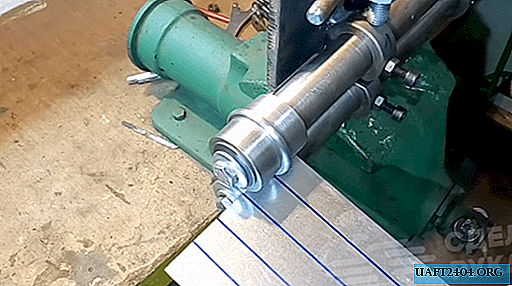

The creasing machine is designed for forming the edges of sheet metal, as well as for rolling sheets, from which pipes for furnaces are then made. You can make a creasing machine for sheet metal processing yourself, but you can not do without a lathe here.

The use of a home-made creasing machine for the manufacture of “notches” on sheet metal allows you to make finished products much stronger, since the grooves made in them act as stiffeners.

Design Features of Creasing Machine

To make a simple creasing machine for zigovka sheet metal, it is necessary to grind on a lathe two shafts with gears at the end. Two bushings must also be made on each shaft of the machine.

Creasing and corrugating rollers are made on a lathe. They are put on the free ends of the shaft. We cut four bushings to get one even edge. Steel strip is welded to the perpendicular side of the bushings.

Then, in the resulting blank, we drill one hole. From a thick sheet of metal, the base is made for a homemade creasing machine. Next, proceed to the assembly of the entire structure. The bushings act as a shaft mount.

It is necessary to weld a nut to the upper part of the base plate of the creasing machine, into which the adjustment bolt will then be screwed - it is responsible for moving the upper shaft in a vertical plane.

For a detailed process of manufacturing a homemade creasing machine for machining sheet metal, see the video on the site.