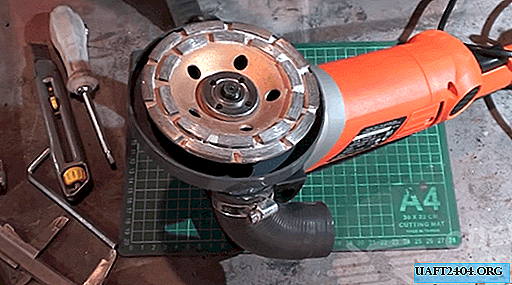

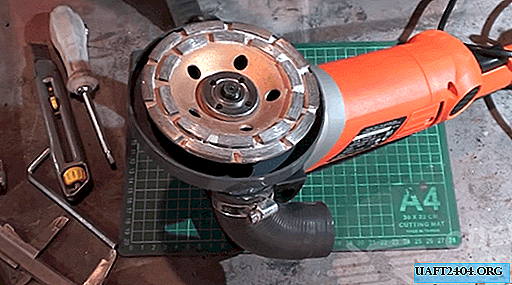

A polishing machine is often used for grinding concrete surfaces. In the process of this "dirty" work, so much dust is usually generated that you have to constantly take breaks. However, this drawback is easy to fix if you make a dust cover for the polishing machine.

To make this home-made casing, you need a pipe for the auto cooling system, as well as pieces of sheet steel and simple metal clamps with a fixing screw. In general, the investments in this case are minimal, and the result is quite decent!

First of all, from a narrow strip of sheet metal, you need to bend the ring onto the gear housing of the polishing machine. Alternatively, you can use a short length of pipe of suitable diameter, in which you will need to cut a small piece.

The main stages of work

An elongated nut is welded to the ends of a homemade metal ring. Then we clamp it in a vice and cut it into two parts using a grinder, and screw in the bolt. Thus, we get a simple but reliable clamping clamp.

Next, on a band saw or using a grinder, cut out a circle of a suitable diameter from a piece of plate. In the center we drill a hole. The edges of the round billet are processed on a belt grinding or file so that there are no burrs left. Then we weld it to the clamp.

The edge part of the casing is made from a piece of strip cut off from sheet metal. After that, we cut a hole in a round plate and weld a piece of pipe, on which a pipe is then put on.

You can see the detailed process of manufacturing and assembling a home-made casing for a polishing machine in the video on the website.