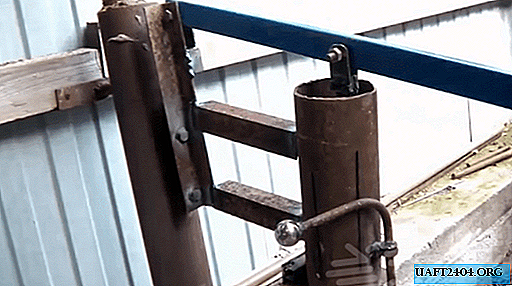

A home-made press for the manufacture of briquettes and euro-woods is useful to those who always have a large number of sawdust that require useful application. To make this press, you will need a piece of steel pipe (diameter of about 100 mm) and other metal parts.

First of all, we cut off a piece of pipe (about 30 cm) with a grinder, we make cuts in it to drain the liquid. Next, from a piece of sheet metal with a thickness of 3-4 mm, we cut a round “crush” (so that it is the diameter of the pipe) and a square plug. We weld the rack from the profile at a right angle to the disk.

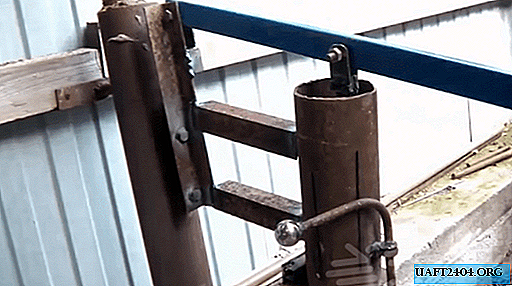

To the bottom of the pipe we attach a section of the profile on which the door hinge will connect, connecting the pipe to the plug. The loop can be welded or put on self-tapping screws.

The process of making a homemade press

From a steel bar of suitable diameter (in this case, a piece of an old bracket is used), we make a “closure” by bending it accordingly. Then we put the washer and nut on the bracket so that it could spin, but did not hang.

Grab the welding nut. We put another nut on the pipe and weld to the first. For beauty, you can add a ball from the bearing to the edge of the closure. Now you need to cut a few pieces of the corner and drill into them mounting holes.

We weld two corners horizontally to the pipe, one to them vertically. We connect the vertical corner to the profile with a bolt, a small plate and a stand under it. Then we fasten this section of the profile with bolts to the pressing part, having welded “ears” with holes on it.

A homemade press for making firewood and fuel briquettes is ready, now it can be planted on removable mounts, for example, to a suitable post or wall. Useful home-made is made quickly and will last a long time!