After a certain time on the grinders, the brushes wear out to such an extent that they simply stop reaching the collector. In this case, their replacement is required. However, not every master knows how to properly repair angle grinders.

In this review, the author talks in detail about the assembly / disassembly of the grinder and replacing worn out brushes with new ones, and also shares useful tips that will be useful during the repair of an angle grinder.

And before proceeding to disassemble the grinder, it is imperative to get the brushes out of their "seats". In some models of angle grinders, to change the brushes, you need to disassemble the case.

But even if you have a grinder in which the brushes can be replaced without disassembling, it is still better to disassemble it in order to see what condition the collector is in.

Step-by-step brush replacement process

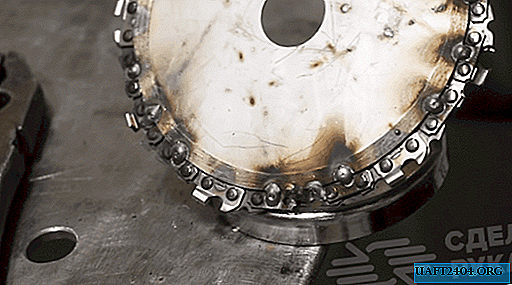

After the grinder body has been dismantled and the electric motor pulled out, it is necessary to conduct a visual inspection of the wiring for damage, as well as pay attention to the tracks.

Paths should not be burnt, and there should be no dust in the gaps between them. If there is dust, then it must be removed. Also, tracks should not be badly worn. However, minimal production is allowed.

If necessary, the tracks can be cleaned with fine-grained emery paper. You will also need to inspect the inside of the grinder. Wires should not be damaged.

If a lot of dust has accumulated during the operation of the angle grinder, then it must be removed with a brush and it is good to blow the case inside.

If everything is in order, it remains only to check the bearings. They should sit tight. Minimum play is allowed. And after that, you can start assembling the grinder in the reverse order and installing new brushes.

Here, in principle, are all the main nuances that are worth paying attention to. But so that the repair of the grinder is complete, it will not be superfluous to also check the condition of the parts that are inside the gear case. If necessary, replace the grease.

Useful advice for unscheduled repairs grinders

Many people wonder what to do if the store could not find exactly the same brushes that were installed in the angle grinder. You can simply buy larger brushes (a difference of 1 mm is normal), and grind them to the desired size.

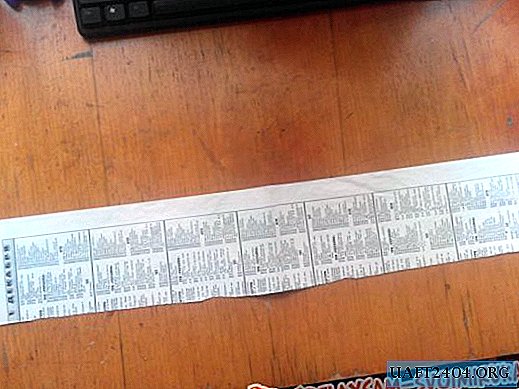

To perform this operation as accurately as possible, you need to make a simple adapt. On a piece of chipboard, plywood (or another flat surface) using a double-sided tape, you need to fix the brush. At the corners, the master twists four self-tapping screws, recessing their hats by 0.5 mm below the surface of the brush.

In this case, the hats of the screws act as beacons. After that, with the help of a bar with sandpaper, you need to remove excess graphite. If you grind the brush by eye, then the surface may turn out to be uneven, which is undesirable.

Details on how to independently change worn out brushes on angle grinders can be found in the video on our website.