When working in a home workshop or garage, you often have to use several types of power tools. That's just sometimes it causes a lot of trouble - you constantly have to get confused in the wires.

However, this problem can be solved once and for all. But only for this it will be necessary to modernize the available power tool (angle grinder, drill, jigsaw, hand milling cutter, etc.)

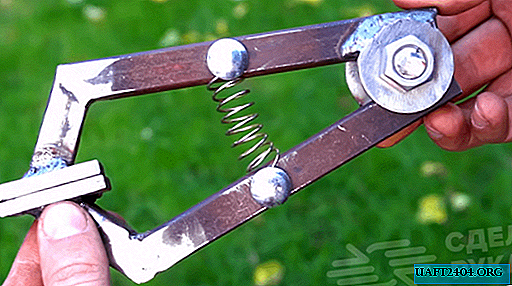

In this case, the author suggests making a quick-detachable cord on detachable connectors. The bottom line is that one extension cable is made with a plug, and the counterpart is built into the body of the power tool. The factory cords will need to be cut.

A dad-mom connection is convenient in that it is securely fixed, and also, if necessary, it can be disconnected very quickly. After such an upgrade, the wires will no longer be tangled underfoot, and it will be much more convenient to use the tool.

The main stages of work

You can install these detachable connectors on almost any tool, but you will have to slightly modify the inside of the case. And the first thing I decided to upgrade the grinder.

If you have a handy drill on hand, this will not take much time. It is necessary to bore a hole in the housing for the diameter of the "outlet".

To fix the reciprocal part of the detachable connection in the housing, the master uses epoxy resin. For greater reliability, this place can be reinforced with fiberglass. As a result, the “tail” of the Bulgarian turned out to be quite reliable and durable.

In the case of an electric drill, a grinder, as well as another tool, the body of which consists of two halves, the "socket" is installed only in one of the parts. This is necessary so that you can later disassemble the tool for cleaning and inspection.

To "reinforce" the epoxy can be used fiber. For more information on how to make a universal cord for a power tool on detachable connectors with your own hands, we recommend that you watch in the video on our website.