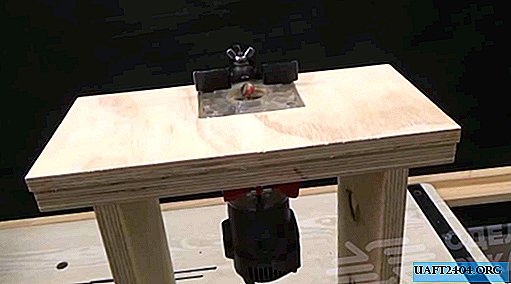

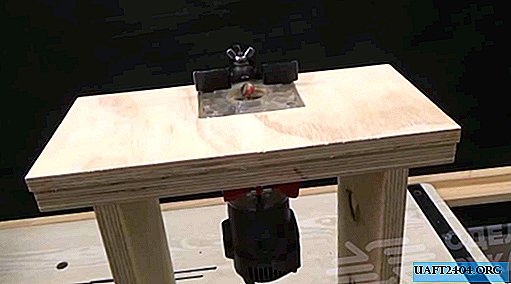

In this review, the author shares the idea of how to make a platform for the edge milling machine with your own hands and at minimal cost. You can use ordinary plywood or OSB for this. In principle, chipboard is also suitable for this purpose.

Thanks to such a home-made site, it is much more convenient to process wood blanks. In fact, it turned out a mini milling table.

First, you will need to cut four pieces of OSB or plywood of a suitable size. In this case, the dimensions of the blanks are arbitrary - at your discretion.

The main stages of work

In one of the workpieces, it is necessary to cut a hole for the plastic support sole of the milling cutter. Fasten it to 4 bolts.

At the next stage, we assemble a box of a rectangular shape: blanks from plywood, cut earlier, are fastened together with self-tapping screws.

After that, the author cuts out another piece of plywood and, using a jigsaw, makes a groove in it. The blank must be screwed to the box so that the sole of the hand mill is flush with it.

Then we install the edge mill itself. In parallel with the milling cutter, the author attaches an emphasis to the blanks. Here, in fact, all the work is fast, practical and inexpensive.

For more information on how to make a site for an edge mill with your own hands, see the video on our website.