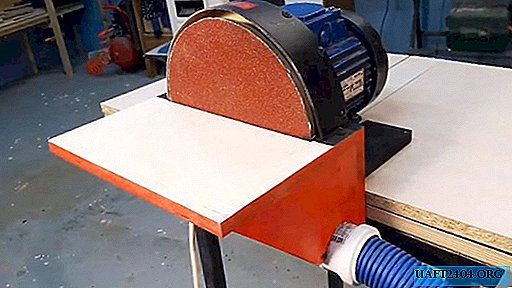

In this review, the wizard shows the manufacturing process of a home-made cutting machine for wood. As a basis, the author uses a small grinder (angle grinder) and a saw blade on wood.

The machine has compact dimensions, so it does not take up much space on the table. A swivel platform with a broach makes it possible to cut wooden blanks of different widths and at different angles.

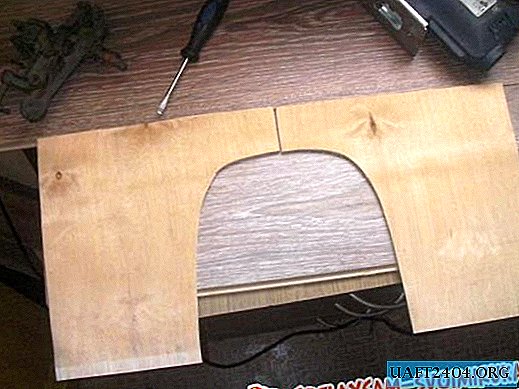

First of all, the author saws off a small bar from a piece of board. On the sides of the workpiece, longitudinal grooves are selected.

In this bar, the author drills a hole for the bolt, and then fastens it to the casing of the angle grinder.

The main stages of work

At the next stage, the author makes two guides from wooden slats, which should fit snugly into the grooves in the carriage.

After that, a turntable is made. The author cuts two pieces of wood, drills holes in them, then connects them together with a bolt.

The author fastens the guides to the top of the turntable. As the base of the cutting machine, MDF sheet is used (you can take plywood with a thickness of 20 mm).

The master attaches the turntable to the base so that the guides are on the side.

At the last stage, we install the grinder. Homemade ready.

For details on how to make a wood cutting machine from a small angle grinder, see the video.