This homemade product is useful to all lovers of outdoor recreation. At the same time, it is quite budgetary, since available materials are used for its manufacture. As the basis of the entire structure, any old gas canister will be required.

The main stages of work

The first is to carefully trim the handle mounting points and remove it. Then we make the markup for the future round-cut along the side walls. Also, for this homemade product, a profile pipe with a length of one meter with a wall thickness of 3 mm is required. We divide it into three segments, and one of the parts is cut at an angle.

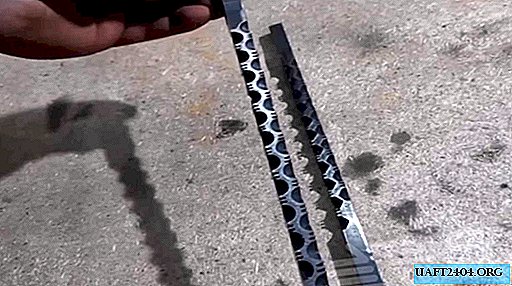

Next, you need to cut the windows in the canister under the pipes - for this we outline the cut lines, and also make a marking in the form of a grid for the places of holes with a diameter of 8 mm on the lower pipe. Alternatively, longitudinal cuts can also be made.

After that, we make slots with a grinder on the sides and with a hammer we bend the resulting grate with holes. In the upper pipe, it is also necessary to make holes for the dimensions of the pipe with oblique sections. At the next stage, we weld all the main elements with a continuous seam.

Homemade stove assembly

We lay the pipes in the canister, laying sections of the profile pipe and weld all the mating parts to each other. Then it remains only to restore the integrity of the canister, for which we weld the cut side part back.

For convenience, you can also make an additional compartment in the back of the canister, weld first a couple of loops, and then only cut through the door. For greater rigidity, it is desirable to strengthen the door with a profile pipe. We also reinforce the canister handle with steel rods of a suitable diameter, slightly shift it down from the original location and weld it.

The advantages of such a stove are that it consumes little firewood. At the same time, it is transportable, like an ordinary canister, and differs in its original appearance.