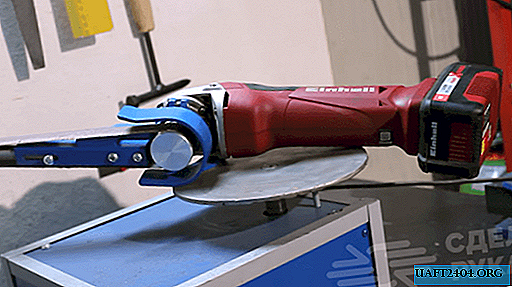

A home-made grinder with a manual stretch, made on the basis of a small battery grinder, is useful when performing various grinding work in a home workshop.

Compared with its stationary "brothers", this version of the home-made grinder is compact in size, and therefore more convenient and practical to use.

Tapes of the required length for a homemade grinder from a grinder can be cut from ordinary tapes for a grinder. Now we proceed to the homemade product. First of all, on a lathe from a round aluminum blank of a suitable diameter, you need to make a drive roller.

The main stages of work

After manufacturing the drive roller, it is necessary to make a clamp that will be worn on the “neck” of the angle grinder housing. To do this, cut the ring from a steel pipe of the required diameter, cut a piece, and then weld two nuts on the edges of the ring. You can weld one elongated nut, and then cut it in half.

A rectangular steel plate is welded to the clamp, and another one of the same size is attached to it. The weld joints must be cleaned with a grinder so that there are no "snot". We drill two holes in the profile pipe and plate, after which we connect both parts together.

On the other side of the profile section, cut out a longitudinal groove and insert a round pipe into it, in which we drill a hole for the fixing bolt. At the end of the tube we weld a “tip” with bearings.

The detailed process of making a grinder from a manual-tensioned grinder can be seen in the video on the website.