In the winter, working with a grinder or grinding indoors is very inconvenient, since a lot of dust is formed, which settles in a thick layer on the surface of walls, floors, workbenches, etc. The best option in this situation is forced ventilation.

It’s not necessary to buy factory hoods in a garage or workshop (all the more so since they are far from always suitable for a particular room). You can make a homemade hood from the engine of the washing machine and improvised materials.

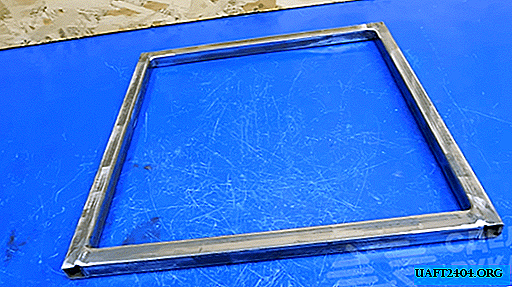

First of all, we cut off the grinder with four identical pieces of the profile pipe. Then we clean the ends and weld a square-shaped frame from these blanks. Welds must be cleaned with a flap disc. Then we weld a square sheet of metal to the resulting frame.

The main stages of work

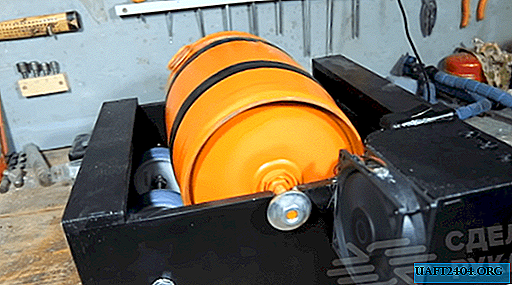

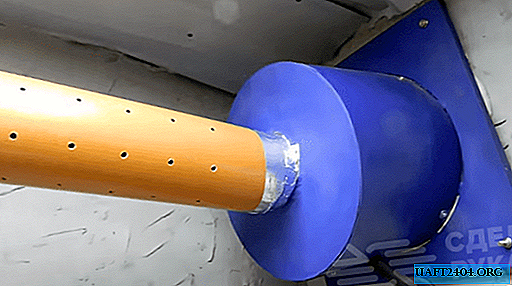

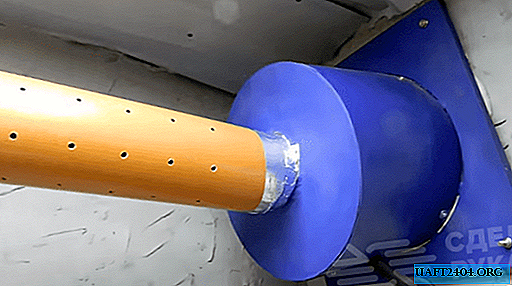

From a conventional sheet metal 1 mm thick using a plasma cutter (or grinder) we cut a rectangular piece. We bend it using a pipe with a diameter of 320 mm as a matrix. Then we weld the joint.

At the next stage, we cut four segments of a strip of metal, bend them with the letter “G” and drill through holes in them of the desired diameter. After that, we fix the obtained blanks to the engine from the washing machine.

In a metal frame, cut a round hole and put on a sheet of metal pipe - we weld just below the middle. Then we make a cover with an adapter on the pipe, and we also attach a propeller to the motor shaft. We assemble the entire structure and install it.

For details on how to make an extract into the garage or a workshop from the engine of the washing machine with your own hands, see the video on the site.