The wooden handle on the hatchet dried up, as a result of which it fell into disrepair, so the author decided to make a worthy replacement for it - but not from wood, but from aluminum.

First of all, the author removes the "stubs" of the wooden handle and removes the rivets. You need to cut one edge of the rivets with a grinder, and then just knock the rods out of the hole.

After that, the author cleans the ax itself and its tail from rust, and drills additional holes in the handle.

Next, from the extruded polystyrene foam, it is necessary to cut two blanks and stick them to the handle of the hatchet.

We recommend reading: casting aluminum into polystyrene foam, an easy way to create any shapes.

The author uses a brush to apply a liquid gypsum solution to the surface of the polystyrene foam.

The main stages of work

At the next stage, we put the hatchet with the “tail” in a container of suitable size (in this case, the author uses a cardboard box) and fill it with sand.

After that, we melt the aluminum, and pour it into the gate. Expanded polystyrene instantly melts, and aluminum fills the space inside the gypsum "cocoon."

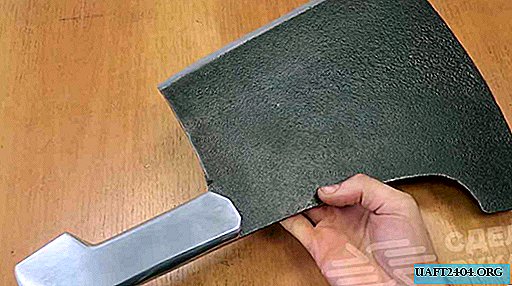

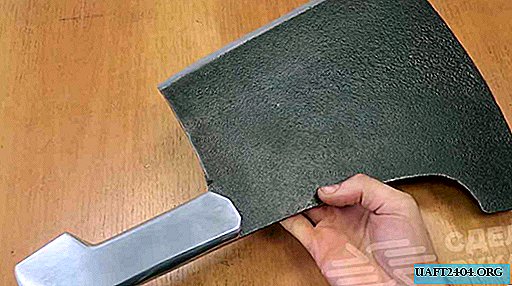

Then you need to break the gypsum and cool the aluminum handle in water. On the band saw we cut off all unnecessary.

Further, with the help of a file with a large notch and sandpaper, the author gives the aluminum handle the necessary shape and noble appearance.

The final stage of work is polishing the aluminum handle and sharpening the ax blade.

For details on how to make an aluminum handle for a kitchen hatchet, see the video on the website.