Share

Pin

Tweet

Send

Share

Send

Materials:

- wood hacksaw;

- bearing with an inner diameter of 22 mm;

- 2 enlarged washers M14;

- nut M14;

- M8 bolt;

- steel pipe d 40 mm;

- 5 bolts M6;

- 11 nuts M6;

- sheet steel 2 mm.

Nozzle making

Unscrew the hacksaw handle.

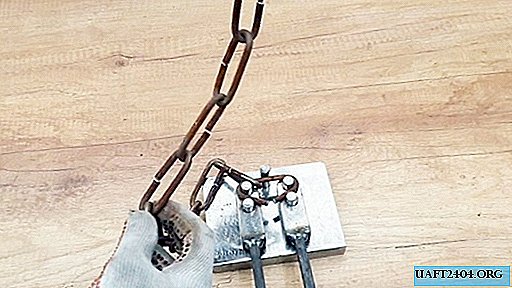

In order for the saw to be able to translate, an eccentric must be made. For this, the washer, bearing, washer and nut M14 are put on the spindle of the grinder. To offset the center of the structure, insert a piece of M8 bolt into the gap between the spindle and the bearing. It must be cut to the height of the bearing. The resulting design is firmly clamped with a nut, so that the eccentric will rotate without friction on the spindle thread.

A similar design will be used to mount the saw, as on the standard protective grinder of the grinder. A piece of pipe is taken with a length equal to the distance between the beginning of the gearbox and the middle of the eccentric bearing. Then it is partially cut into 2 rings. The cut should be more than half. The notch line runs opposite the edge of the seat for attaching the casing.

Next, you need to cut the bottom ring.

An M6 nut is welded to the edges of the slice. With their help, the ring will tighten like a clamp when tightening the bolt.

A hole 1 mm larger than the outer diameter of the bearing is drilled in the hacksaw blade. Above and below it is a little boring. Given the quality of the hacksaw steel, work will take time.

2 identical rectangular plates of arbitrary size are cut from sheet steel. A 40 mm hole is drilled in their center.

One plate is welded with a pipe clamp.

At the corners of both rectangles, a 6 mm hole is drilled. They should be opposite each other.

Hacksaw markings are made on the marking of holes, as on plates. They are drilled, and then bored with a file in order to be able to move the canvas. Sharpen in both directions in the horizontal direction from the centers of the holes.

For aesthetics, spray paint can be used.

To use the nozzle, you need to grease the contact surfaces of the web and pressure plates with solid oil.

Details are pulled together by bolts and nuts. You need to pull it loose. Locknuts are placed on top so that the blade does not loosen or pinch.

An eccentric is assembled on the grinder, and the nozzle is placed instead of the protective casing. All saber saws can be used. After applying the equipment, you can remove and use angle grinders as usual.

And we start work on sawing.

Share

Pin

Tweet

Send

Share

Send