Share

Pin

Tweet

Send

Share

Send

Necessary materials and tools

For manufacturing, a circular is required, you can use a hand saw or an electric jigsaw. We need a drilling machine, a drill, a set of drills, carpentry glue and a set of hardware for fixing elements. Such shelves are mounted in unheated rooms, the dimensions are consistent with the pitch and width of the rafters.

Shelf manufacturing process

Draw a sketch of the shelf detailing each item. It will take a few details.

1. The basis. The length equals the height from the ceiling to the floor.

2. The bottoms and sides of the drawers. Dimensions are selected taking into account the estimated number of tools and spare parts. The distance between the shelves is about 30 cm, the number is a multiple of the height of the shelf. In our case, 8 boxes will be installed.

3. Details of the stop fixed to the wall. In our case, there will be two rows of boxes, we must keep this in mind during the preparation of the sketch.

4. Partitions, rotary levels, etc.

The number and nomenclature of elements may vary, taking into account the model you personally invented.

First step

Work begins with the manufacture of part of the shelves fixed to the wall. On a circular saw, cut a large sheet into pieces, prepare all the structural elements.

Cut a part of the sheet, it will be fixedly nailed to the wall, cut six elements to fix the three supporting brackets. We have thin plywood, in order to increase the strength of the parts in the future it will stick together. Accordingly, not three, but six parts are required.

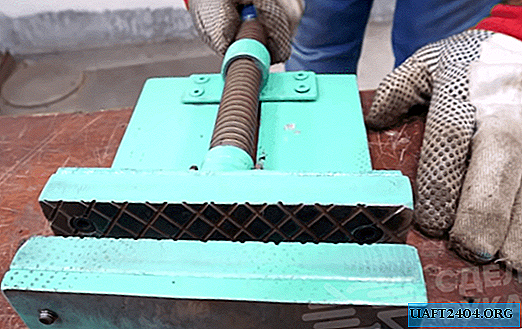

Drill holes in them under the rolling axis, cut off the corners that will interfere with the rise. Holes are made in all details, after gluing their depth doubles. Before drilling, the parts are firmly fixed, this way coaxiality is achieved.

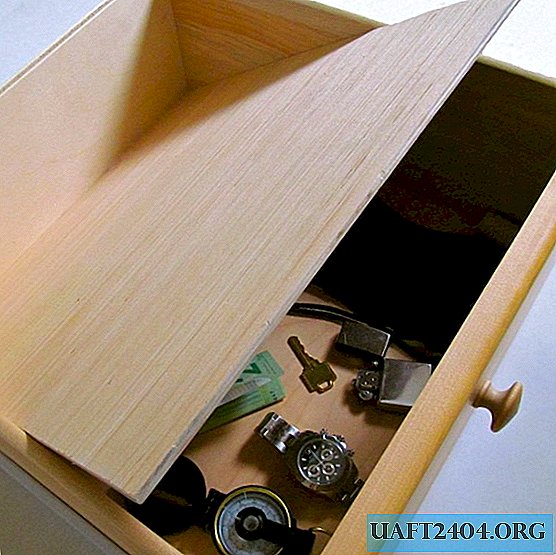

Due to the fact that the shelves are movable, one corner must be cut so that it does not touch the base while lifting the structure. Boxes are fixed with special elements, which, when lifted, constantly keep them in a horizontal position. If you do not remove the corners, then they will abut against the wall of the shelf, the device will not function. You can cut off in a radius or in a straight line, it does not matter. The main condition is to ensure free rotation.

Start assembling the blanks in a single design. First attach two slats to the shield, and then fix the sidewalls. It is necessary to fasten it on the dowels and self-tapping screws, insert special joiner fixed nuts into the holes of the axles. Attach the assembled part to the wall, use the level to maintain horizontal position. It should be fixed very firmly with dowels, check the reliability. The item must support your weight, it holds the entire structure.

Second phase

Proceed to sawing parts for the rotary boxes, but they need to remove the two corners of the sidewalls. The side walls will be double, respectively, it is necessary to double the number of blanks.

The assembly is done according to the method described above, you can use only self-tapping screws, but then it is recommended to increase their number.

Ready-made boxes will later be attached to the rear shield of the shelf and be able to constantly maintain a horizontal position when it is raised. This effect is achieved by the features of their fixation.

The back side of the drawers is attached to the back wall with pianos or any other hinges; they create a movable fulcrum. A through hole is provided on the opposite side of the box for the second pivot axis.

Grind the surface of the boxes with a grinder, attach to the bottom of the loop.

Prepare long slats. They will be located on the sides of the drawers and fixed to them with hinges. The length of the rails is equal to the length of the back wall.

Drill holes for the hinges. In our case, a plastic pipe was used as a hinge, the same holes should be prepared. The location of the holes depends on the distance between the drawers.

Fix the hinges of the drawers to the wall, place them evenly and in such a way that they do not touch each other while turning.

Insert pieces of plastic pipe into the holes; they perfectly serve as hinges. The length of the pipe is equal to the total wall thickness of the boxes and long strips.

Connect the two extreme elements and check the operability: raise and lower them. They must freely make all movements and constantly be in a horizontal position. There are problems - eliminate them, everything is normal - start assembling the shelves.

Assembly

In the upper part of the wall, fix three strong hinges, screw them to the element mounted on the wall.

Loop the first box to the end of the bottom of the wall.

Insert the plastic tubes into the holes and put on two long straps on them. It is they who hold the drawers in an upright position when lifting the shelf to the ceiling.

In turn, insert all the boxes into the tubes and screw them with hinges to the wall.

If there are doubts about the strength of plastic tubes, then you can make a wooden axis, the outer diameter should correspond to the nominal diameter of the tubes. Cut the axle into pieces of appropriate length and hammer into tubes.

If the angles of the long slats abut when lifting, then their angles must also be cut. To improve the appearance, process on a milling machine. Immediately you can slightly increase the diameter of the holes. In them, the tubes should rotate freely, and sit rigidly in the walls of the boxes. To reduce friction between the strips and boxes, large washers can be placed.

Drill holes in the center of each hinge and connect all the elements with the countersunk head bolts. This will prevent spontaneous separation of the structure. Saw off the long ends of the bolts with a hacksaw, cover the nuts with caps.

Check performance. Everything is in order - according to the same scheme, attach long slats to the shelf parts mounted on the wall, tighten with bolts.

To facilitate the lifting of the structure, gas lifts or springs can be installed. Using the same technology, you can make a second, third, etc. shelf.

It is recommended to nail two stops to the bottom, they will make it possible to maintain the structure at a selected angle, which will facilitate access to the drawers and improve the design of the room.

On this, all the complex work is completed. It remains to come up with fixing the shelf in the raised position. But first, you need to make a wooden frame and nail it securely to the floor beams.

Then, automatic latches are fixed to the shelves and frame. The shelf is held in a raised position, to lower it is necessary to move the latches. There are many options, choose for yourself the most simple and convenient in execution.

Conclusion

The shelf is very comfortable, and in complexity it belongs to the category of simple products. Dimensions vary depending on the specific features of the structure, do not be afraid to make independent decisions. To improve the appearance of the surface can be coated with stain or any paint on wood.

Share

Pin

Tweet

Send

Share

Send