Share

Pin

Tweet

Send

Share

Send

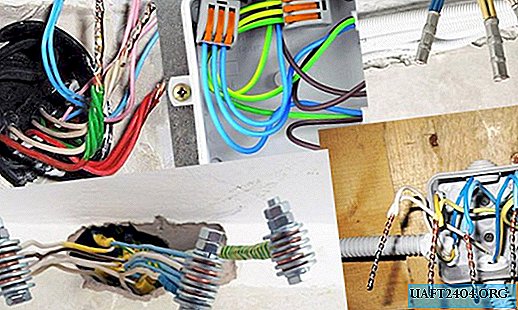

The reasons for altering the old wires of home electrical systems are mass. In particular, this concerns the reconstruction of the old housing stock. Aluminum wiring in two cores is susceptible to corrosion and scattering. A characteristic reason for this condition is the very poor insulation of many Soviet cables. Chemically, aluminum is more active than copper (the main material of pure cables). But it is in its purest form. Aluminum in air is coated with a strong oxide film and, in theory, should be more durable. But when the insulation sheath is strewed or water flows into it at a time when the wire is not energized, the wires are destroyed. The second factor is fire hazard. In some old houses, the insulation is made ... of ordinary fabric. Which for decades, of course, has decayed. Modern polymer cable sheaths are also much better than Soviet cambric worn for decades.

Ordinary twist of two wires

The abundance of new docking methods does not completely cancel the usual twisting. In conditions of extreme repair, this is almost the only right way out. The simplest perm of two wires, subject to an approximate estimate of the current strength (do not put a thin wire on a strong current), works almost always. But it is forbidden to connect copper with aluminum. They have relatively close resistance indicators, but copper is still less - and this creates an excellent thermocouple. The melting temperature of aluminum is a little higher than six hundred degrees, so this twist is a fire hazard a priori.

Pros: anyone can do it. There would be wires and hands.

Cons: Twisting is not airtight. Over time, the contact weakens, resistance increases due to poor contact, the structure starts to heat up ... and then everything is as in the case of twisting copper with aluminum. That is why this method is prohibited by the rules of the PUE.

Solder twist

An attempt to solve the problem of fragile contact in the conditions of ordinary twisting. Actually, mechanical twisting is performed, and then you need to solder the contact point. Need a standard soldering iron, solder and flux. Solder - both ordinary tin-lead and newer variations. Traditional rosin and new synthetic resins can also be a flux. The method works for a very long time and therefore is beneficial for capital docking for many years.

Cons: all the charms of the "tin plague" or oxidized lead (depending on what was more in the solder). Soldering helps, of course, but better, more reliable methods of isolation. Boxes with diluted wiring most often pop up to the ceiling, which is why problems with soldering in weight with the head bowed are common. The problem of combining copper with aluminum is also not solved at all.

Wire welding

A new and popular method, which is increasingly preferred by installers. A compact inverter, electrodes are taken, after which the ends of the formed twist are caught. Fast, practical, no fuss with solder, monolithic.

Pros: Reliability. With a properly homogeneous seam, conductivity is simply excellent.

Cons: Almost none. Guaranteed will require the qualifications of the welder, whether it is considered a minus is an individual matter. In general, the requirements for welding qualifications are much more than for simple work with an electrician.

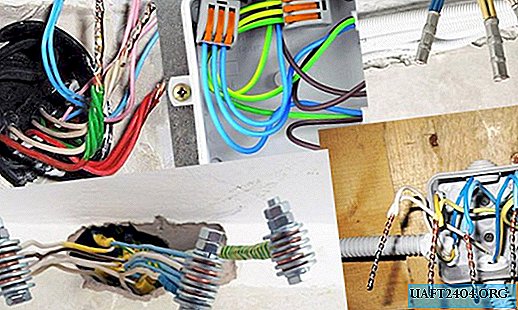

Terminal blocks

Terminals are a fairly convenient and aesthetic type of connection. Simple assembly of the assembly does not require much effort and time.

Pros: Simple, fast, without too much stress. You can connect wires of different metals.

Cons: To connect a stranded wire, it will first need to be pressed into a special tip. Do not connect more than two wires. Periodically it is necessary to check the connection node.

Wago Connection

Wago - This is a flat plastic box with an all-in-one concept. We clean the wire, as when twisting, insert it into the clip-latch - done. Suitable for a combination of any number of wires, there are a lot of varieties for different current strength and the number of contacts. Ideal for quick installation of electricians.

Pros: perfect sealing. Finally, you can connect copper with aluminum, just follow the markings on the connectors. You can also contact the cores of different diameters, which is a plus in the installation of a "motley" fleet of wires.

Cons: Vago is expensive. It is very expensive. Vago boxes do not change anything except the same boxes, "on the knee" this can not be collected a priori. Therefore, this connection method is used either with a very good budget for an electrician, or when you need to connect wires leading to expensive electrical equipment.

Bolted connection

Full compliance with the original name. A bolt, nut and three washers provide a solid connection between two different wires. The selection of a bolt from the appropriate material makes the joint durable and in terms of electrical differences. The main problem in this case is the dimensions. A lot of things are used as a junction box. From store boxes to instant Nescafe cans or tooth powder. But their fundamental property is one - the bolted connection does not go there. Or fit, but then it will cling to adjacent wiring and shorten. Therefore, such a solution in a house where you have to hide the junction box, it is better not to use it at all.

Crimping

It is carried out by a special device. Another type of almost ideal, but very time-consuming options for connecting wires. However, this is more than compensated by the highest insulation abilities. Crimping is relatively inexpensive, the main part of the payment is the work of a specialist.

The above wiring connection methods are selected in full accordance with the repair or construction strategy. In the ideal case, of course, it’s better to drive it into a crimping or Wago, but in fact it usually turns out that such money is not pledged to the electrical peripherals. In urgent circumstances, you can use any type of connection, observing safety precautions and laying high-quality power networks. All “interim solutions” should be immediately redone for capital decisions as soon as possible. This will significantly improve fire safety at the facility, as well as improve the quality of electric power transmission with reduced current losses, which can result in significant material savings.

Share

Pin

Tweet

Send

Share

Send